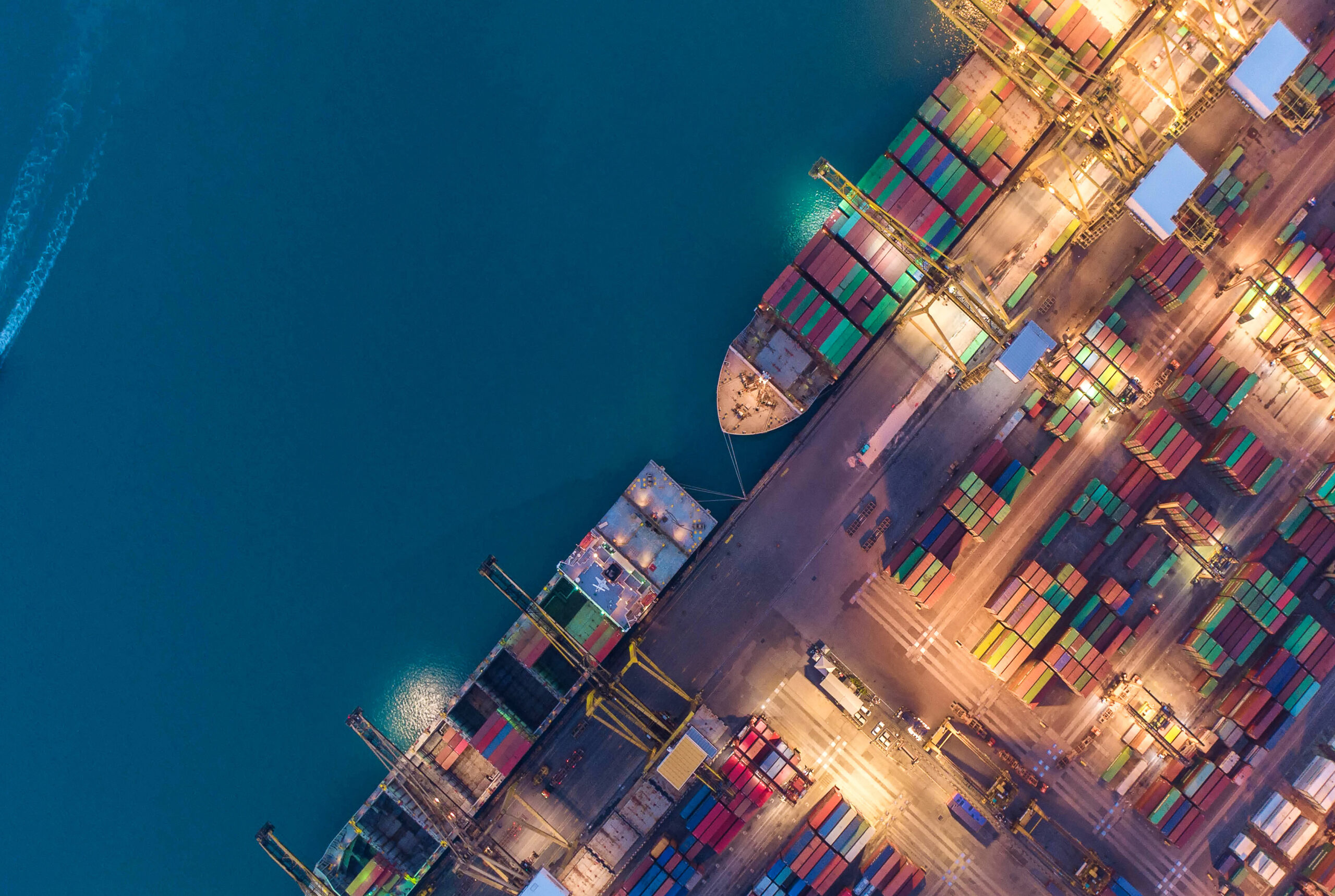

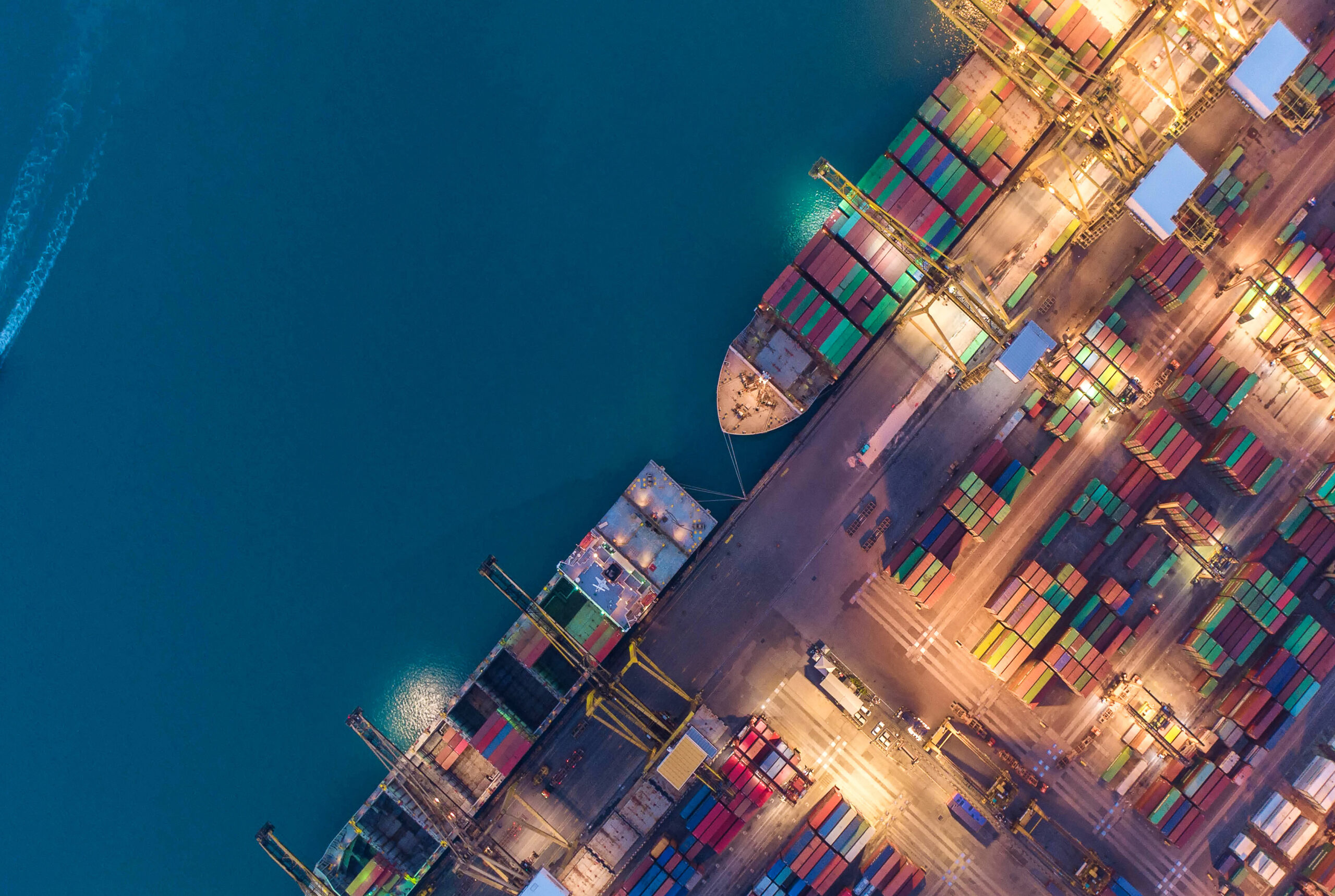

A battle for the best supply chain

The world’s biggest companies have invested significantly in creating a competitive edge through supply chain restructuring. CEOs such as Tim Cook at Apple, David Taylor at Procter & Gamble and Mary Barra at General Motors come from supply chain backgrounds. It’s now up to others to follow suit or fall behind.

Modern supply chains still need to perform the core function of getting products to market. But they must also be responsive and agile enough to perform in today’s more volatile, uncertain, complex and ambiguous (VUCA) business environment.

VUCA was first coined as a military term describing the more fluid, uncertain and multilateral world that emerged following the Cold War. It has now found its way into the lexicon of strategic business management and is a useful framework to gauge how well supply chains are positioned to cope with the growing pressures they are under.

The escalating US-China trade war and ongoing uncertainty around Brexit are very real and immediate examples of the difficulties facing companies’ supply chains.

US companies sourcing components and products from China have had to cope with the impact of recent tariff hikes. Walmart, the world’s biggest retailer, has publicly said it’s exploring alternative suppliers in different countries to overcome, or at least mitigate, the impact on its customers and its business.

Brexit has the potential to generate problems overnight for supply chains – and as the 31 October deadline approaches, a managed exit seems far from certain. Time is running out to implement contingency fall-backs, and if politicians strike a last-minute deal then companies may feel they could have used the resources invested in mitigation planning for other activities.

Environmental concerns have also intensified the VUCA pressures on supply chains, forcing businesses to re-think many aspects of their operations. Climate change has created more extreme weather patterns and businesses must assess the developing physical risk they create in their supply chains.

They must also analyse the practicalities of fast-evolving environmental regulation and the impact it will have on the raw materials used, the manufacturing processes they employ and the carbon footprint they generate. Where businesses fall short of regulations, they will face increasingly stiff sanctions and suffer reputational damage.

The challenge is to create supply chains that are nimble enough to side-step developing and unexpected problems, and that allow companies to take advantage of opportunities at short notice –whatever shape they arise in.

These hurdles must be overcome against a backdrop of ever-rising customer expectations. The demand for immediate service that started with fast-food giants like McDonald’s now permeates every market as a result of the ‘Amazon effect’ and the impact of e-commerce.

If supply chains cannot work within immediate timeframes, customers will go elsewhere. According to research from PwC, 32 per cent of shoppers will stop purchasing from a favourite brand after just one bad experience. There is a very real and steep downside to a poorly functioning supply chain.

Developing e-commerce capabilities is incredibly important, but it’s also challenging. E-commerce channels are growing at an annual compound rate of 18 per cent and on top of the heightened customer expectations that e-commerce generates, it has also quickened demand for omni-channel capabilities across other sectors. Customers want a fluid experience that allows them to compare, buy and return products using any combination of channels and devices.

It’s exceptionally difficult for retailers with a combination of physical stores, online shops and telesales operations to reliably deliver products to a consistent standard, in fluctuating volumes and compressed timeframes. And this challenge is facing businesses in almost every commercial sector.

Companies can no longer run individual supply chains separately and expect to survive in the medium to long term. They need to merge their physical and digital channels to create a seamless customer experience.

Beyond e-commerce, advancing technology is changing every aspect of companies’ operations and underlying supply chains – a disruptive force that businesses need to harness.

In the automotive sector, for example, a race is now underway to design and deliver affordable electric vehicles for the mass market. Autonomous vehicles are also becoming a reality, while manufacturers are also exploring the use of 3D printing to produce certain components.

Technology has changed the entire automotive industry: from the products sold to the way they are designed, manufactured, marketed and delivered. This has ramifications for every aspect of the supply chain and is forcing automotive companies to find new suppliers or revamp existing relationships.

The paradox of technology’s disruptive influence is that it also offers many of the solutions needed to overcome these challenges. Where companies can digitise their supply chain and create the necessary enterprise oversight, they can then identify vulnerabilities and inefficiencies.

This insight will enable them to target improvements and accelerate their competitive performance against peers. But executive teams can only realise this potential if they understand how to leverage new and existing technologies to positive effect.

Transforming a traditional supply chain into an omni-channel, digitised, automated, and data-driven function is not something that can happen overnight. It is a journey comprising of highly detailed individual stages that need to be aligned with an overarching, enterprise-level strategy.

Many businesses have already taken significant steps to reinvent their supply chains and make them more resilient and responsive to the evolving challenges of today’s commercial landscape.

It’s these businesses that will develop the corporate agility to navigate today’s changeable market dynamics and ultimately rise above their competitors.

Amid this fast-changing environment, there are opportunities. Standard Chartered is partnering with clients to support their ambitions in the future of supply chain management. We are helping clients to unlock value from their financial supply chains by providing insights, analytics and early sources of funding to suppliers in the procurement cycle.

Malinda has over 17 years of experience in procurement and supply chain re-engineering, ERP implementation, digital transformation and change management.

Prior to joining Standard Chartered, she worked for Apple, Hewlett-Packard, Novartis & Syngenta and was primarily responsible for the redesign of complex cross-functional business processes. She achieved significant improvements in productivity, cycle times, quality and customer experiences. In addition, she has in-depth expertise in harnessing technology as a business enabler and for creating competitive business edges.

She has delivered several successful supply chain transformation projects across various countries in Asia.